Key Technologies

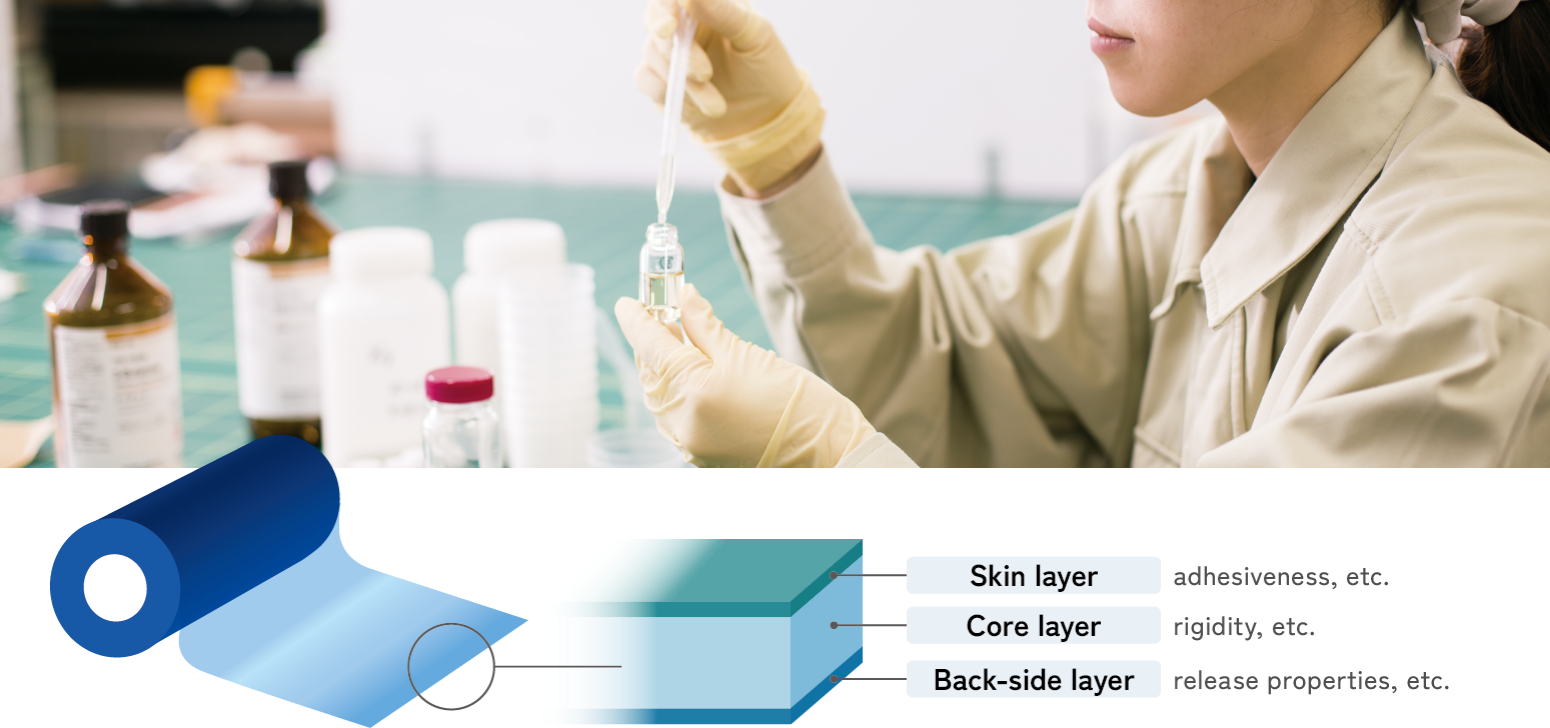

Resin Formulation and Layer Structure Design

Know-how and technologies for required product functions

- Technologies for formulating resin, coating agents, and various additives

- Technologies for optimizing the structure and composition of each film layer

Processing Technologies

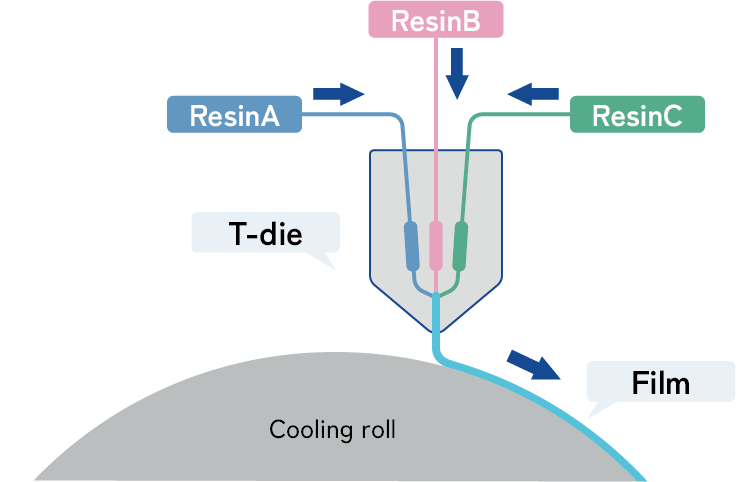

Multilayer Co-extrusion Technology

Used to manufacture laminate films by extruding more than one resin from a multilayer die at the same time. Production of films with various functions such as heat-sealability, heat resistance, impact resistance, printability, and easy-open properties can be realized by adjusting the ratio of constituent resins of the respective layers as well as their thickness.

[Typical Products]

- Easy peel film

- T.A.F.™

(Cast co-extruded multilayer film) - CP

(Cast polypropylene film) - T.U.X™ (LLDPE film)

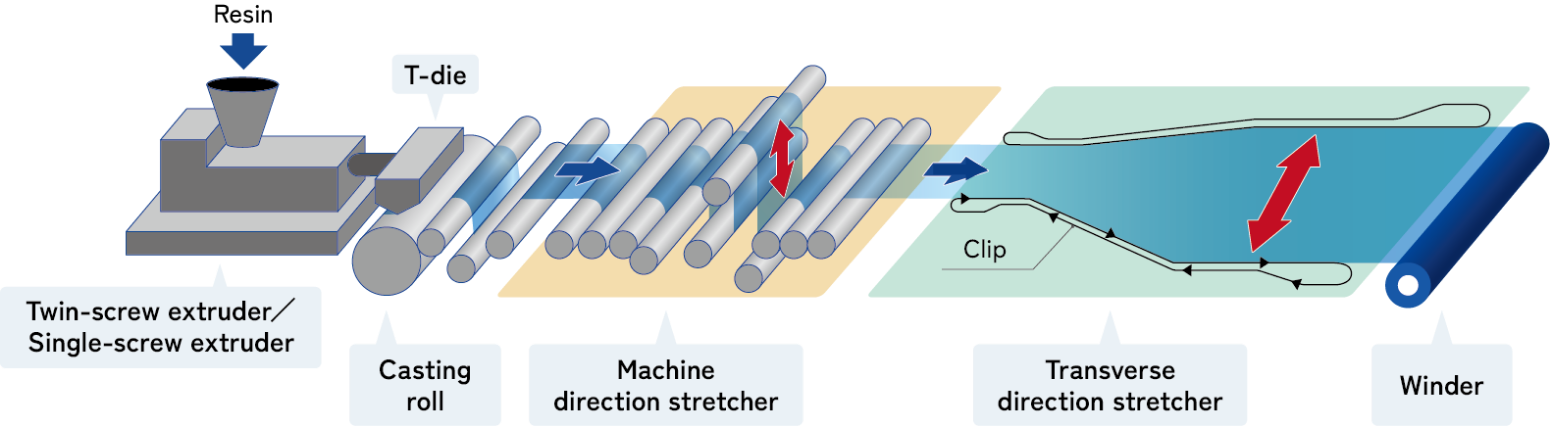

Biaxial Orientation Technology

When plastic film is heated and stretched in one direction, its molecules realign themselves. Orientation is a technology used to produce high-performance film by repeatedly stretching the film in both the machine and transverse directions (biaxial orientation) in order to improve functions like transparency, stiffness, strength, and heat resistance via molecular realignment.

[Typical Products]

- OP

(Biaxially-oriented polypropylene (BOPP) film) - ECONEIGE™ (Milky-white BOPP film)

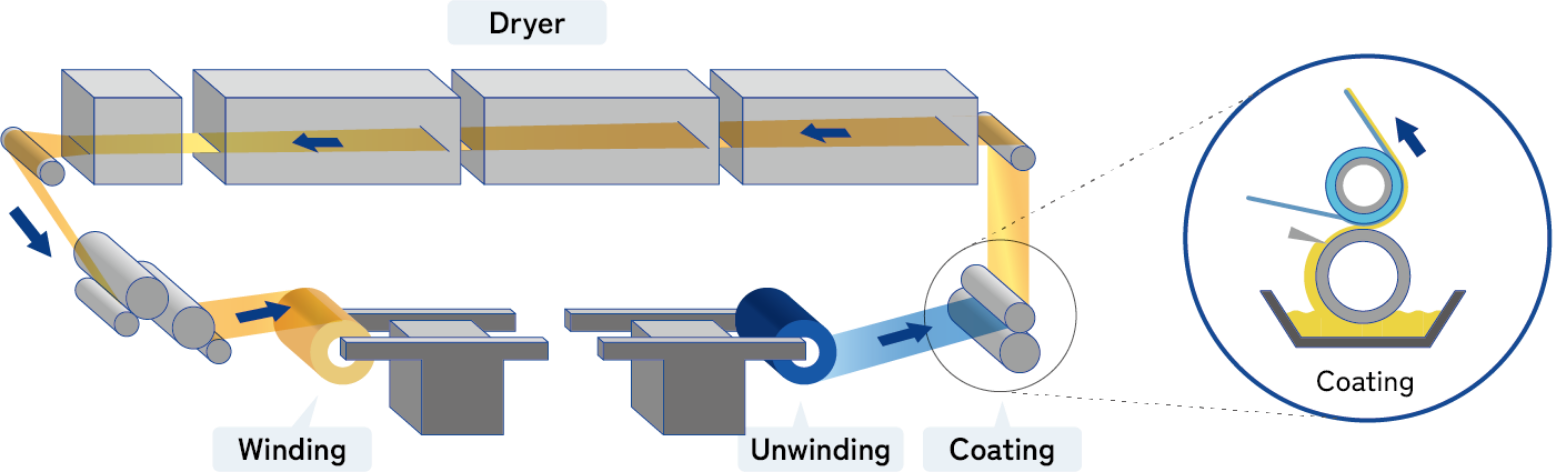

Coating Technology

Used in applying different coating agents to produce various functional films. The right choice of coating agents enables us to make superior films that are impermeable to oxygen and water vapor, releasable, antistatic, and sealable.

[Typical Products]

- A-OP™

(Polyvinyl alcohol coated BOPP film)

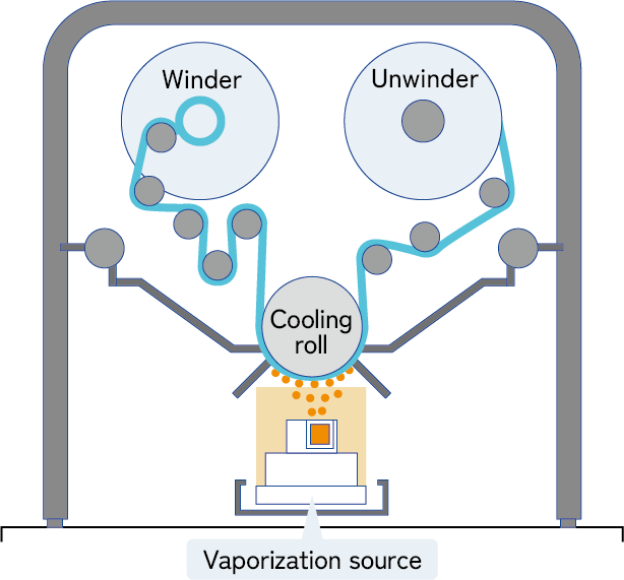

Vapor Deposition Technoogy

Used to vacuum deposit metal, such as aluminum, or inorganic substances onto films in order to make them resistant to oxygen, water vapor, and more.

[Typical Products]

- ML (Aluminum-metallized film)

- TL (Transparent vapor deposition film)

Sheet Molding Technology

Used to evenly knead various additives into a resin, forming a sheet with a uniform thickness, whose surface is then imprinted with a specific pattern depending on how it's to be used.

Foaming Technology

Used to generate sheets with uniform foam layers for added cushioning and other required product functions.